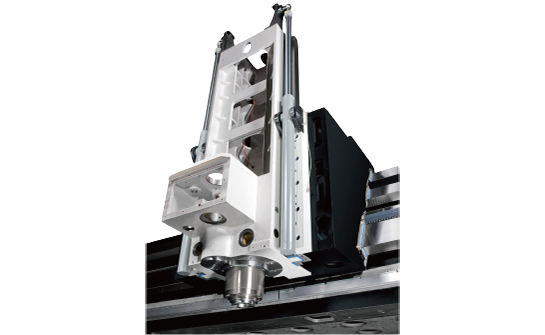

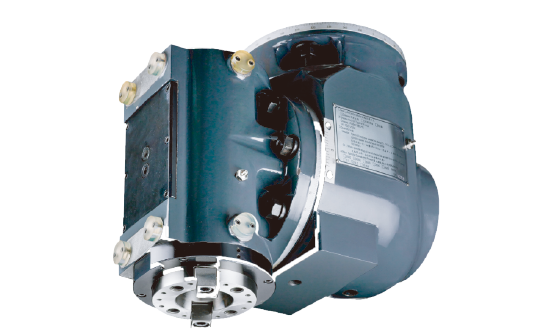

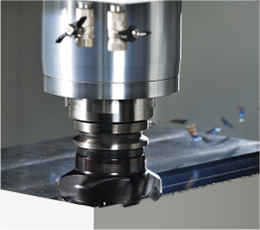

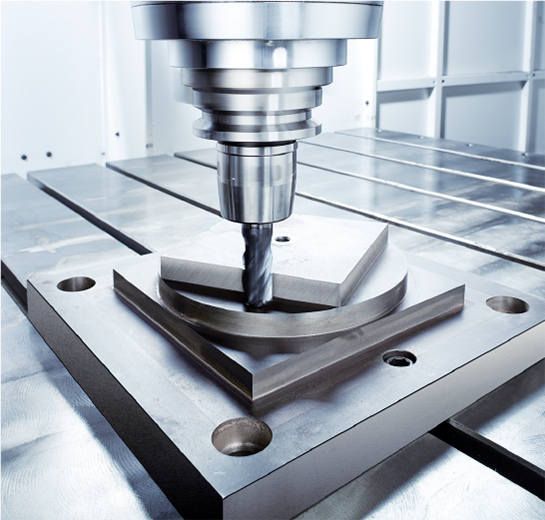

High efficient spindle

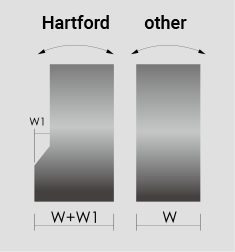

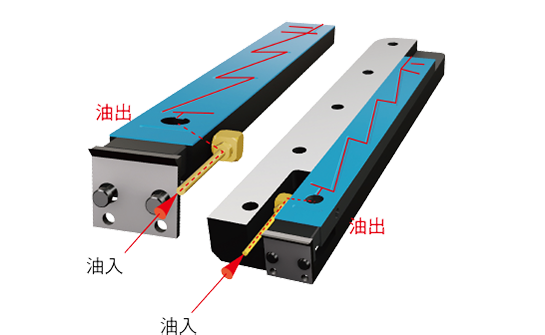

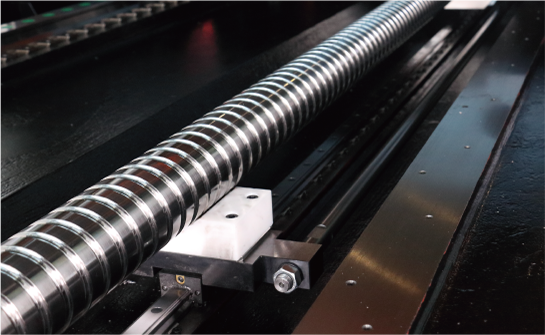

Box Guideways Hybrid Air Suspension and Environment Thermal Displacement Compensation

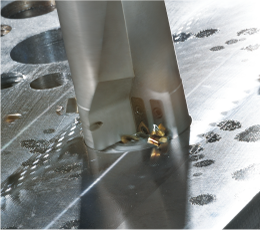

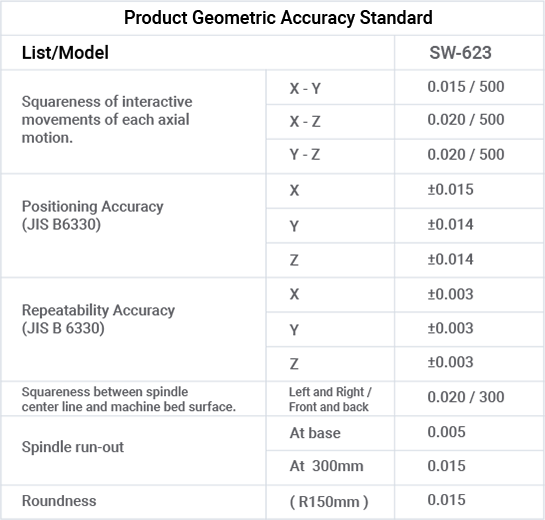

Improved machine accuracy

1. Box Guideways Hybrid Air Suspension: Quadrant error reduced by 50%, 30% reduction in backlash error.

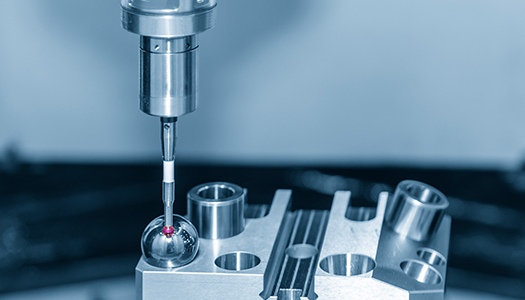

2. Spindle run-out within 5μm.

3. Double column below 6 meters, machine thermal displacement can be reach within 0.03mm.