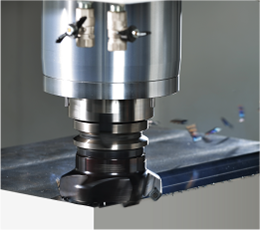

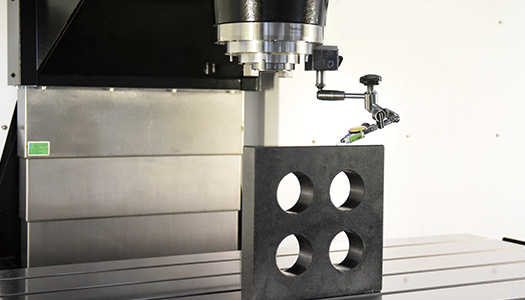

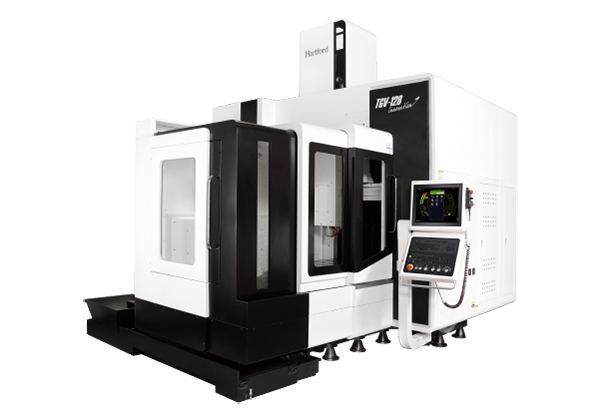

High-Quality, High-Rigidity Spindle

Spindle runout ≤ 6 μm

- B30K Spindle Torque: S1/S6: 8.1 / 10.55 N·m

- Spindle Thermal Expansion: < 20 μm (during 8 hours of variable-speed operation from 2,000 to 15,000 rpm)

- Spindle Runout: ≤ 6 μm (measured with a 300 mm test bar in-house)