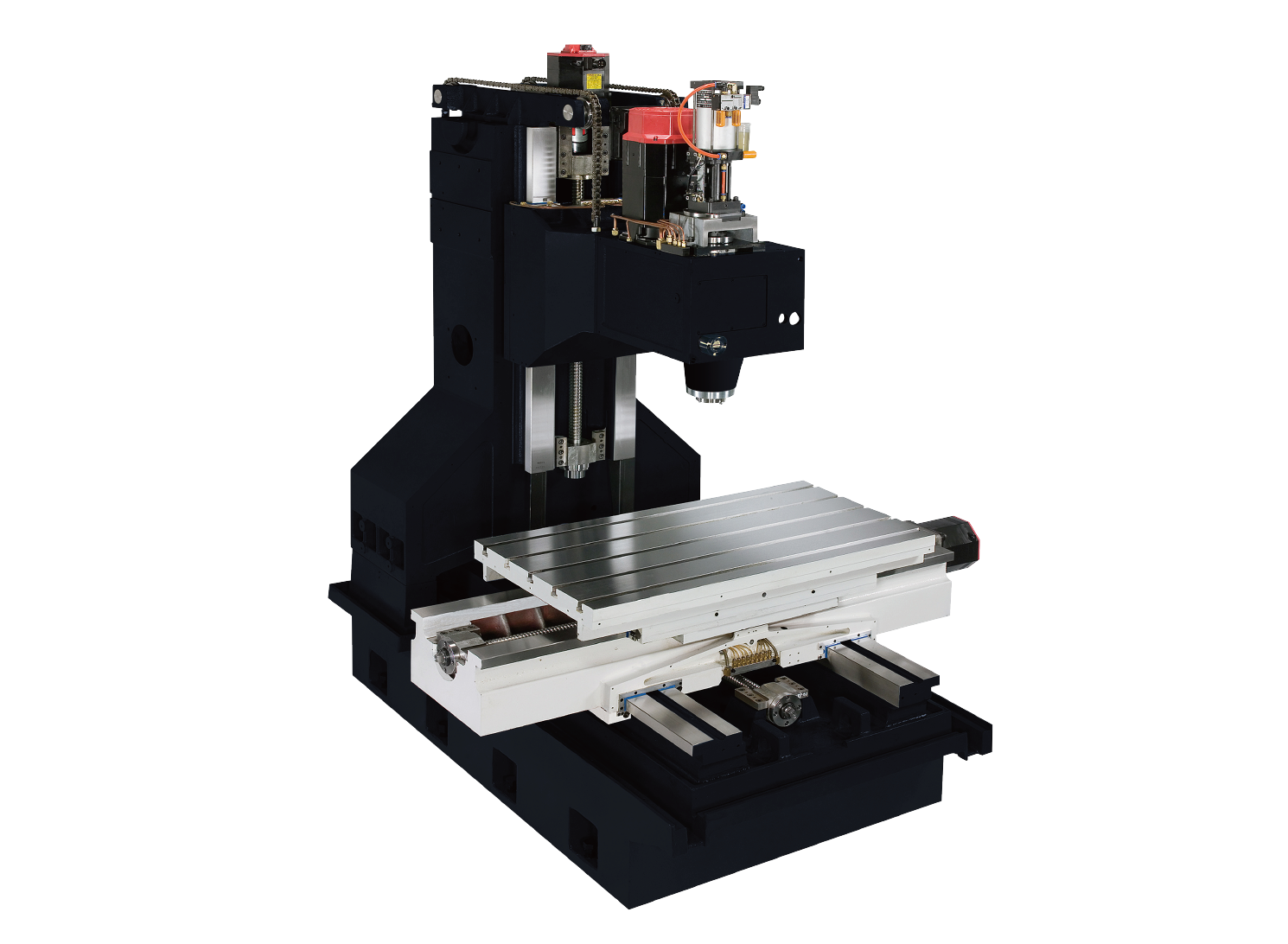

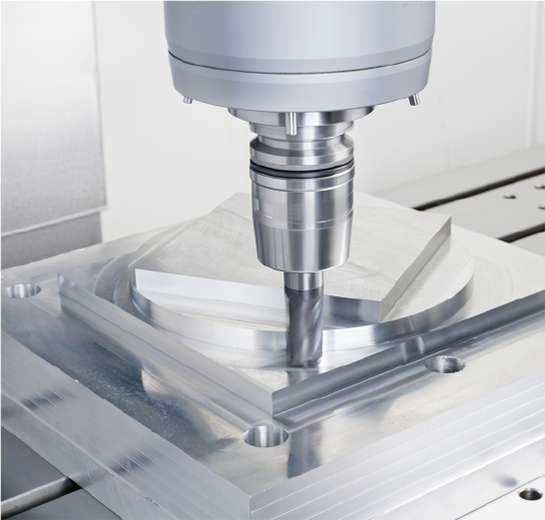

Optimum Structure & High efficiency Spindle

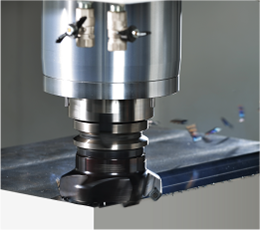

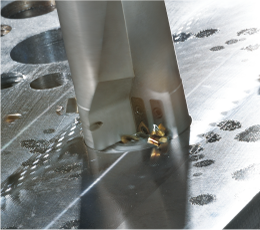

Increase efficiency for small but heavy cutting workpiece

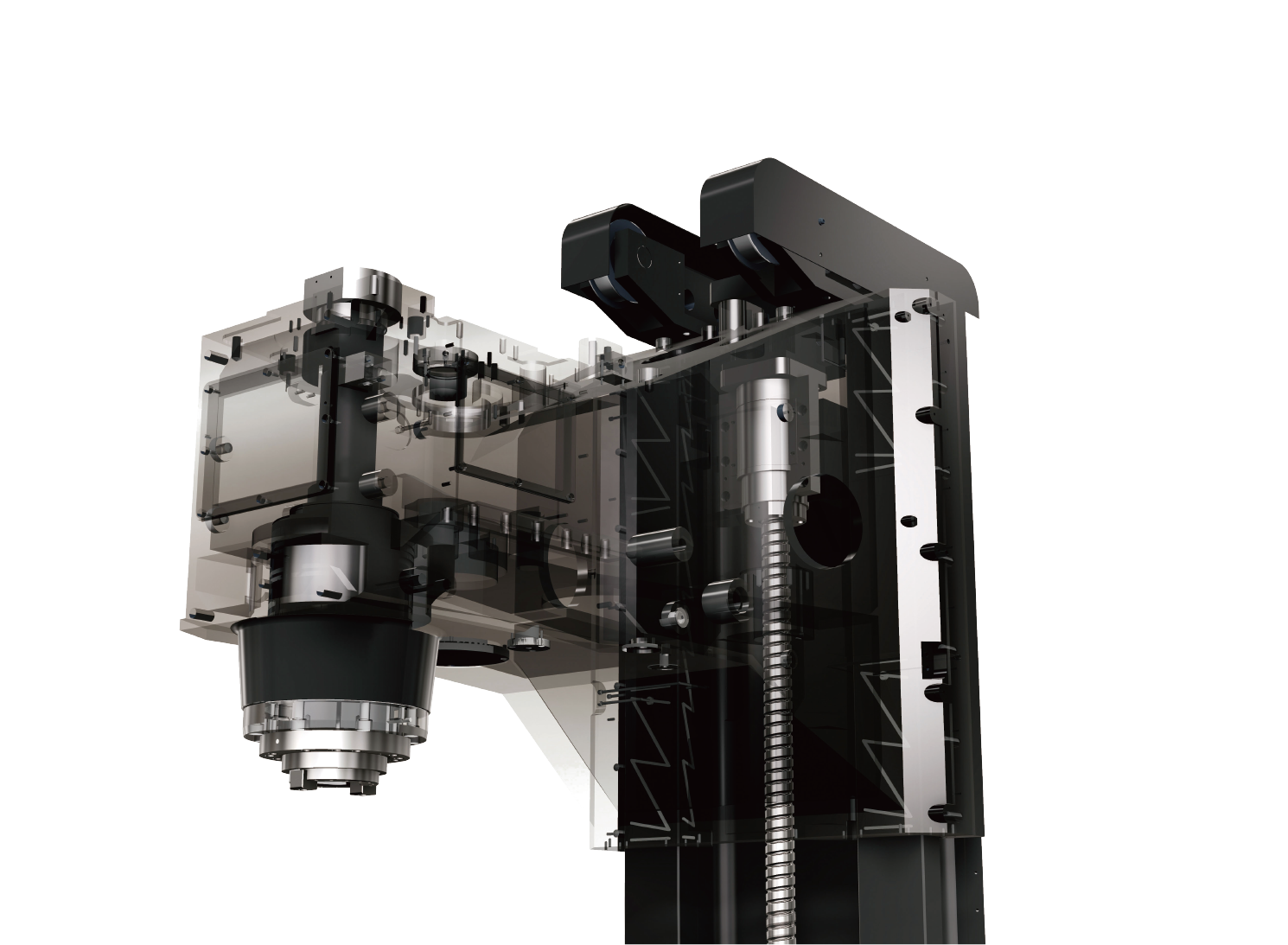

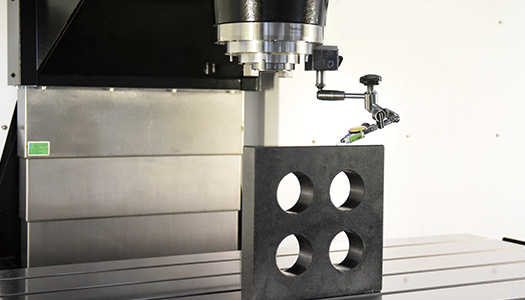

1. One-piece spindle housing design, increase machine rigidity and cutting performance.

2. Reducing weight to reduce acceleration stresses and increase positional accuracy.

3. 100% self-made high precision Gear type and Pulley type #40 spindle

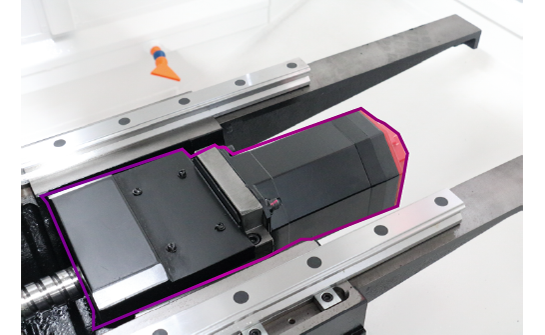

4. Oil/fluid separation device, extend the file of cutting fluid (available with PRO-1000)