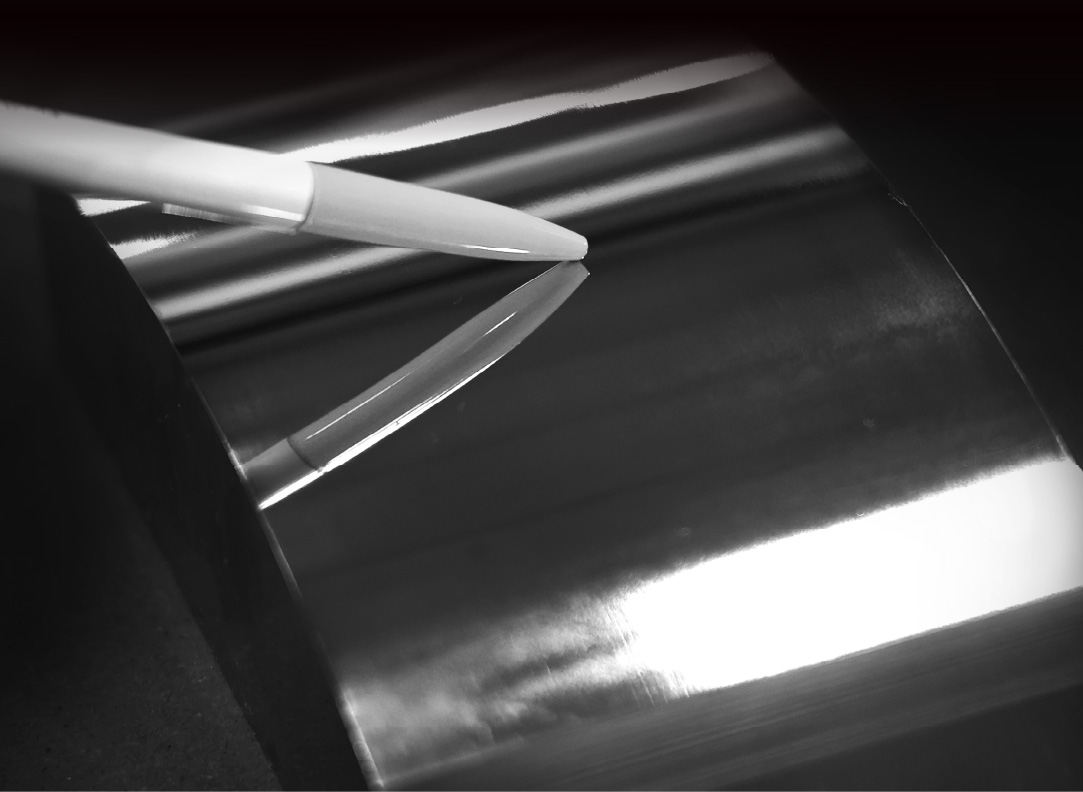

Mirror Mold (Steel)

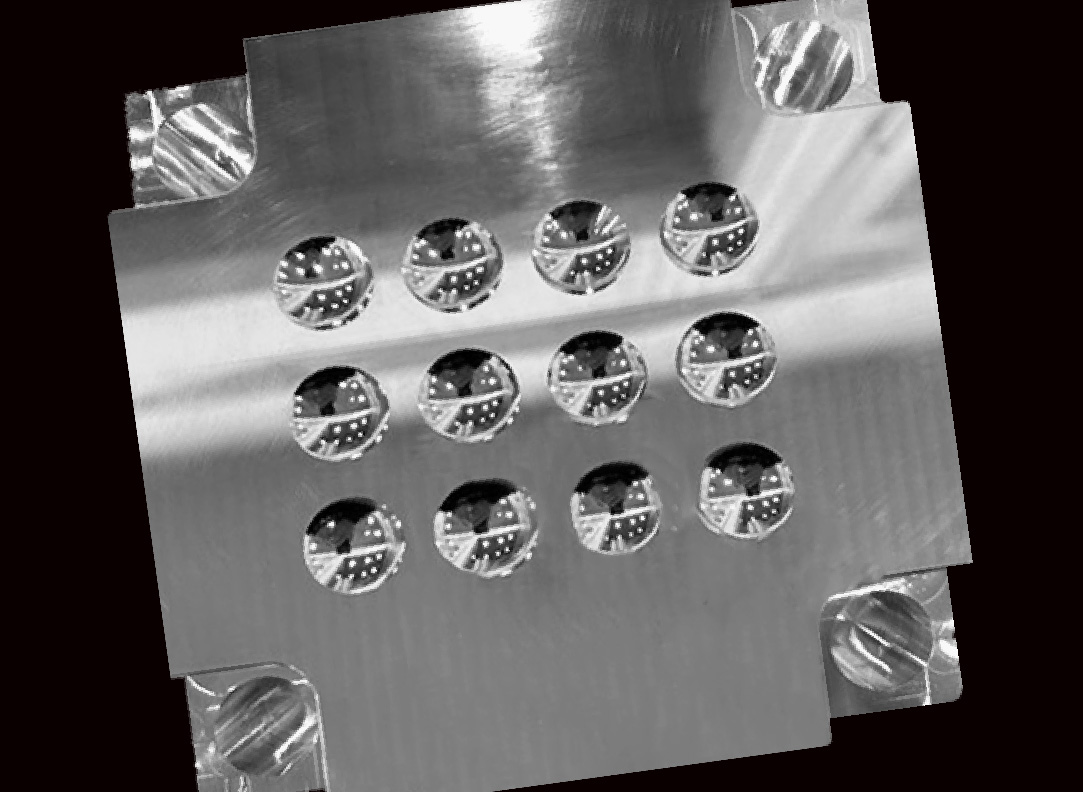

Mirror Mold (Aluminum)

Mirror finishing not only enhances the aesthetic appeal of products, but also improves the durability, corrosion resistance, and specific optical performance of workpieces.

Industrial Applications

- Optical Instruments:

Products such as lenses and microscopes require mirror finishing to enhance optical performance. - Automotive and Aerospace:

Certain automotive components and aerospace parts require mirror-like surfaces to improve appearance and corrosion resistance. - Medical Equipment:

Surgical tools and medical instruments demand highly smooth, pore-free surfaces to ensure hygiene and functionality.

Mirror Mold (Steel)

Workpiece Features:

- Surface roughness as low as Ra 0.126 μm

- Continuous processing with R2 ball end mill up to 64 hours

Applied Technologies:

- Use of PCDR ball end mills

- MGPS micro-level precision machining system (processing variation within 0.2 μm)

Mirror Mold (Aluminum)

Workpiece Features:

- Surface roughness as low as Ra 0.03 μm

- Continuous processing with R2 ball end mill up to 36 hours

Applied Technologies:

- Use of PCD ball end mills

- MGPS micro-level precision machining system (processing variation within 0.2 μm)